The difference between EPDM with Natural Rubber

2025-08-15

Here’s a concise comparison between **EPDM (Ethylene Propylene Diene Monomer)** and **Natural Rubber (NR)** in terms of their properties, applications, and key differences:

---

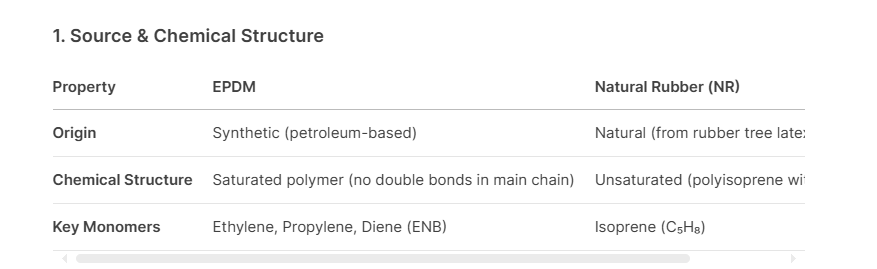

1. Source & Chemical Structure**

**Why it matters**:

- EPDM’s saturated backbone gives **excellent resistance to oxidation, ozone, and weathering**.

- NR’s double bonds make it **more reactive** (better elasticity but prone to degradation).

---

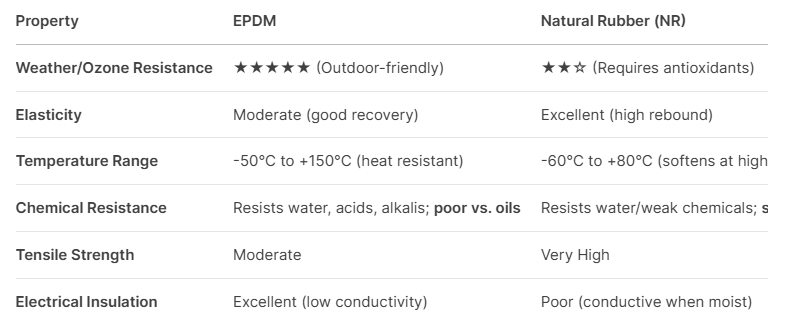

2. Key Properties**

3. Common Applications**

**EPDM**:

- Automotive weatherstripping, seals (resists UV/ozone).

- Roofing membranes (waterproof, durable).

- Coolant hoses, gaskets (handles heat/steam).

- Electrical insulation (cable coatings).

- **Natural Rubber (NR)**:

- Tires (high grip, low heat buildup).

- Medical gloves, balloons (flexible, biocompatible).

- Vibration dampers, shoe soles (shock absorption).

---

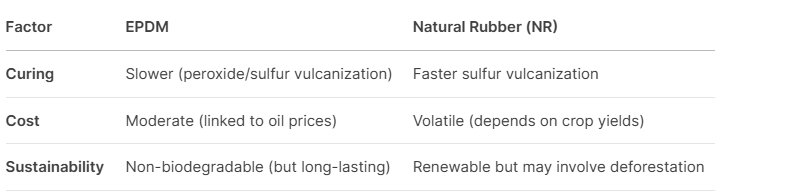

4. Processing & Cost**

-5. Which to Choose?**

- **Pick EPDM if you need**:

- Long-term outdoor use (UV/ozone resistance).

- Heat/chemical resistance (except oils).

- Electrical insulation.

- **Pick Natural Rubber if you need**:

- High elasticity (e.g., tires, dynamic parts).

- Biodegradability or biocompatibility.

- Cost-effectiveness for high-volume uses.

**Quick Summary**

- **EPDM** = Synthetic, weatherproof, heat-resistant, but less elastic.

- **NR** = Natural, super-elastic, biodegradable, but degrades outdoors.

For example:

- **Car door seal?** → EPDM (lasts decades in sun/rain).

- **Surgical glove?** → NR (flexible, safe for skin).

Let me know if you’d like a deeper dive into a specific aspect!

Previous: