HEBEI FENGMING PLASTIC PRODUCTS CO., LTD.

PHONE:+86-15130165775

TEL:+86-311-85851653

FAX:+86-319-3252989

E-mail:contact@fmseal.com

ADD:Yawo Village, Changzhuang Township, Wei County

Contact

Copyright: Hebei Fengming Plastic Products Co., Ltd. 冀ICP备13011107号-1 Powered by:300.cn

Navigation

NEWS CENTER

Contact

ADD:Yawo Village, Changzhuang Township, Wei County

TEL:+86-311-85851653

FAX:+86-319-3252989

E-mail:contact@fmseal.com

HEBEI FENGMING PLASTIC PRODUCTS CO., LTD.

Our company has accumulated rich experience and made outstanding achievements in the design and development of sealing strips for automobiles, high-speed rail, subways, containers, refrigerated trucks, ships, building doors and windows, industrial equipment, etc.

How to judge the quality of EPDM rubber strips

Source:

Release time:

2020/03/11

Page view

[Abstract]:

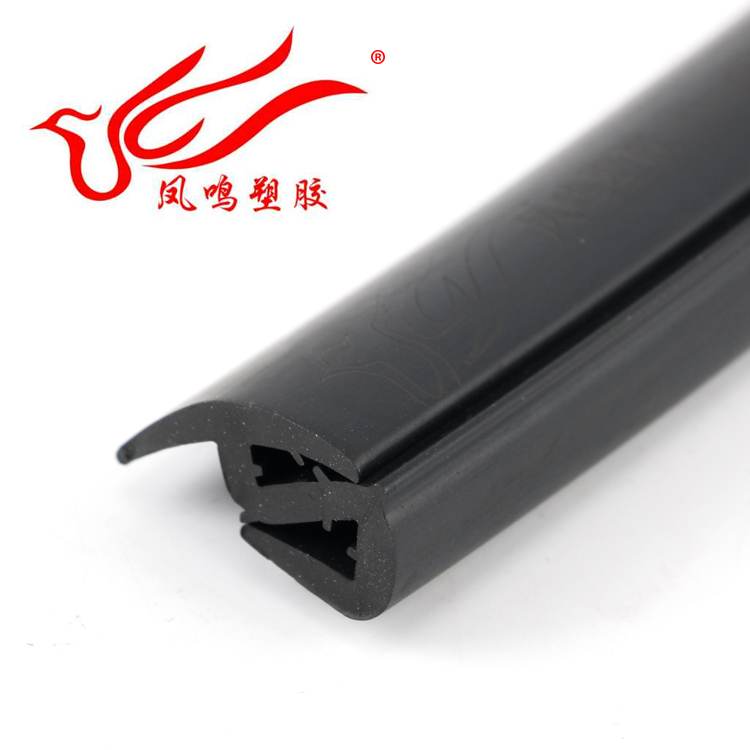

EPDM rubber seal is a very common type of seal nowadays. So how to identify the EPDM strips?

1. Taste. The secondary rubber strips will have a certain odor, especially pungent. Normal rubber and plastic seals will only have the taste of plastic, and even if they are of good quality, they will not smell at all.

2, appearance. The appearance of the secondary sealing strip is very rough at first glance, the hand feels very hard, and there is no tension. On the other hand, the appearance is shiny, soft and pull.

3. Specific gravity. The specific gravity of the second sealing strip is particularly heavy, because the filler used in the production uses heavy calcium or talcum powder and other filling materials, which will increase the specific gravity of the sealing strip, and the good sealing strip will be directly Light calcium carbonate is used as a filling material.

4. Install the door and window sealing strips on the profiles or directly wrap them on the plastic profiles and place them in a high-temperature place for drying. The secondary glue strips will pass through the high temperature, the contact surfaces of the profiles will change color, and the surface will be stained with dust. , And there are yellowing and oil seepage.

5. Use your nose to smell what it smells. EPDM strips have a rubbery taste. Although he is a synthetic rubber, it is still rubbery, so it also has a rubbery taste. Rubber and plastics have a plastic taste. The rubber and plastic in the industry is actually modified PVC, which is different in taste.

6. Burn the rubber strip with fire. The biggest difference between rubber plastic strip and EPDM rubber strip is that the rubber and plastic are black ash after burning, and there will be some stickiness. After burning, the yuan-ethylene-propylene rubber strip is white ash, which becomes black with a pinch.

Previous article:

Industry Features of Composite Seals

Characteristics of container seals

Next article: