The differences between EPDM and PVC

2025-05-27

The differences between EPDM and PVC:

Material Composition

EPDM (Ethylene Propylene Diene Monomer): A synthetic rubber made from ethylene, propylene, and a small amount of diene monomer.

PVC (Polyvinyl Chloride): A plastic polymer derived from vinyl chloride monomers, often blended with plasticizers.

Flexibility & Durability

EPDM: Highly flexible, weather-resistant, and maintains elasticity in extreme temperatures (-40°C to +120°C).

PVC: Stiffer (unless plasticized), less resistant to temperature fluctuations, and may become brittle over time.

Weather & UV Resistance

EPDM: Excellent UV, ozone, and weather resistance; ideal for outdoor use.

PVC: Prone to degradation under prolonged UV exposure unless stabilized with additives.

Chemical Resistance

EPDM: Resistant to polar solvents, acids, and alkalis but swells in petroleum-based oils.

PVC: Resists oils and fats better but is vulnerable to some solvents and plasticizer migration.

Applications

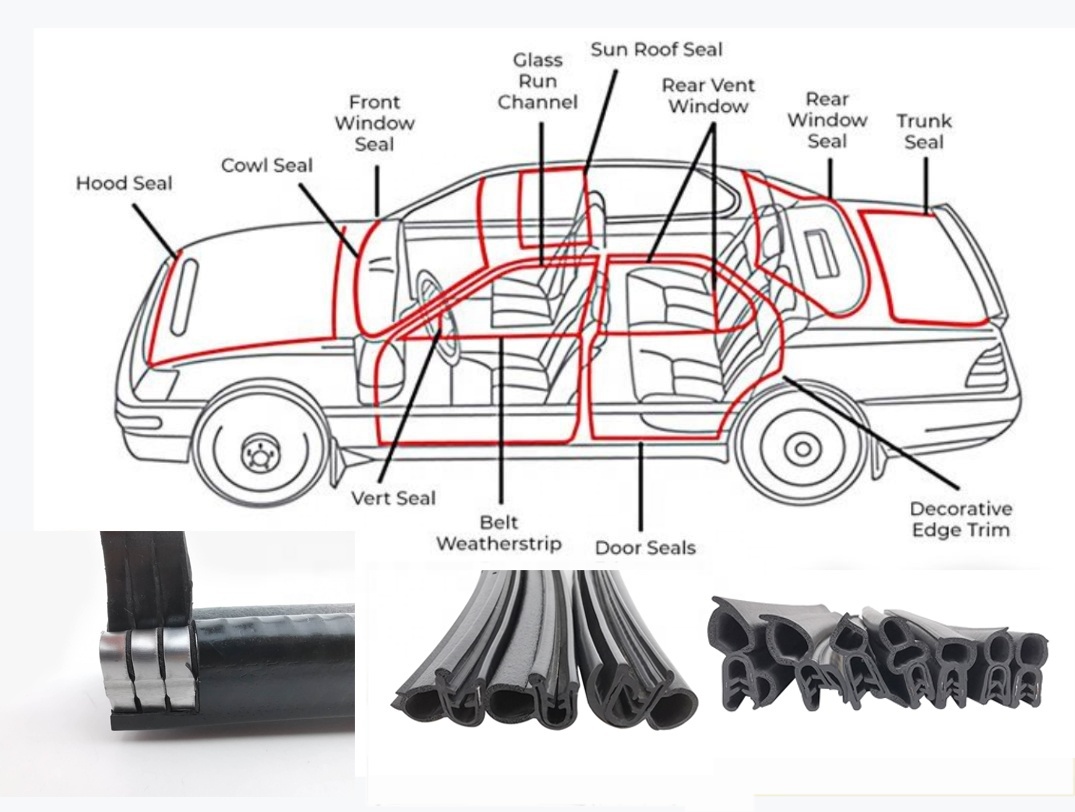

EPDM: Roofing membranes, automotive seals, gaskets, and outdoor electrical insulation.

PVC: Pipes, window frames, cables, inflatable structures, and synthetic leather.

Environmental Impact

EPDM: More recyclable and environmentally stable.

PVC: Contains chlorine; may release harmful dioxins if burned improperly.

Cost

EPDM: Generally more expensive due to superior durability.

PVC: Cheaper but may require more frequent replacement.

Key Summary: EPDM excels in longevity and extreme conditions, while PVC is cost-effective for rigid or short-term applications.